We have known that CNC milling is a common type of CNC lathe machining from the previous papers. Today, we are going to talk about CNC milling machines.

Description Of CNC Milling Machine System

Spindle Box

The spindle box comprises a spindle box and a spindle drive system for clamping and driving the tool rotation. Spindle speed range and output torque have a direct influence on machining.

Feed Servo

The feed servo system consists of a feed motor and a feed actuator. The relative motion between the tool and the workpiece is realized according to the feed speed set by the program, including linear feed motion and rotary motion.

Control System

Control system is the center of the CNC milling machine movement control, implementing the CNC machining program control machine tool processing system.

Auxiliary Devices

They are hydraulic, pneumatic, lubrication, cooling system and chip removal, protection, and other devices.

Base Parts

The machine tool foundation usually refers to the base, column, beam, etc, which is the foundation and frame of the whole machine tool. Generally, these base parts are large sizes.

Characteristics And Composition Of CNC Milling Machine

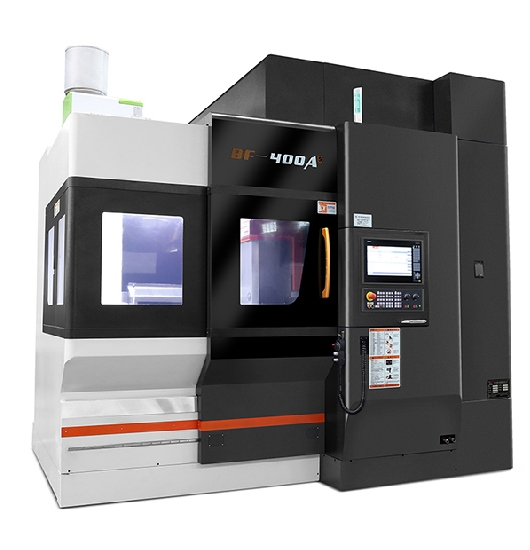

Vertical CNC Milling Machine

The main body of the CNC vertical milling machine is mainly composed of the base, column, saddle, workbench, spindle box, and other components. The five major parts of the main body are made of high-strength castings and molded by resin sand, with a stable organization to ensure good rigidity and accuracy of the whole machine. The three-axis guide pair adopts high-frequency quenching and plastered guide combination to ensure the machine operation accuracy, and reduce friction resistance and loss. The three-axis drive system is composed of a precision ball screw and servo system motor and equipped with an automatic lubrication device

Horizontal CNC Milling Machine

It is the same as the general horizontal milling machine, and its spindle axis is parallel to the horizontal plane. To expand the processing range and expand the function, a horizontal CNC milling machine usually uses the increase of CNC turntable or universal CNC turntable to achieve 4, 5 coordinate machinings. In this way, not only the continuous rotary profile on the side of the workpiece can be processed, but also can be realized in an installation, through the turntable to change the station, "four side processing"

Vertical And Horizontal CNC Milling Machine

At present, this kind of CNC milling machine is rare. Because the spindle direction of this kind of milling machine can be replaced, it can achieve both vertical processing and horizontal processing. And this type of milling machine has functions of both vertical and horizontal CNC milling, so the use is wider, the functions it is more complete, and the choice of processing object is wider, bringing a lot of convenience to users. It is especially suitable for multi-variety and small-batch products that require both vertical and horizontal processing methods.